Awọn ọja

Ga-ṣiṣe Downhole milling Tools

Ohun elo ọja

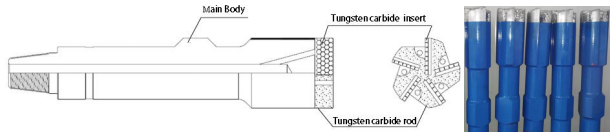

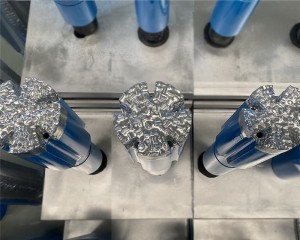

Mu awọn bata ọlọ isalẹ alapin bi apẹẹrẹ:

Ara akọkọ gba irin alloy alloy giga-giga (4145H) lati rii daju iṣiṣẹ didan ati imunadoko labẹ ọpọlọpọ titẹ liluho ati ipo iyara iyipo.Nibayi, a gba ipele giga tungsten carbide meterial lati ṣaṣeyọri milling fast.Stabilizer ati ita yeri fun ijekuje ọlọ ati taper ọlọ le ti wa ni apẹrẹ bi nilo.

Tungsten carbide ifibọ

· Superloy

Filler ti o dara fun elegede, okun ati awọn ọlọ taper.

O dara pada fun ijekuje Mills.

Jakejado titobi ti o wa.

Julọ gaungaun.

· Irin Muncher

Mills yiyara ju mora milling irinṣẹ.

Din nilo liluho titẹ nigba ti milling.

Fi awọn gige didan silẹ laisi ète fun idoti lati gbele lori.

Ṣe agbejade idoti pẹlu iwọn kanna.

Gige irin dipo ti lilọ o.

· Opti-ge

Kekere idoti.

Yiyara ROP.

Aye gigun.

Isalẹ titẹ ati iyipo awọn ibeere.

16 gige ojuami ati 8 gige egbegbe fun kọọkan ojuomi.

Ẹka ọja

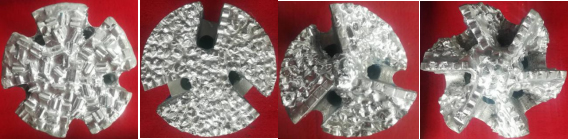

Concave / Alapin / Blade Isalẹ ijekuje ọlọ

Ti a lo fun milling bit, konu, iwọn ila opin, awọn eyin grapple, paipu iwẹ, isẹpo ohun elo liluho, awọn ẹya ẹrọ fifa kanga ti o jinlẹ, apoti, olupin omi ati awọn irinṣẹ liluho gigun miiran.

Petrozhr ijekuje ọlọ wa o si wa ni orisirisi awọn atunto ati geometries.Imọ-ẹrọ ọlọ ti ilọsiwaju wa ati alurinmorin ti o ni iriri rii daju pe eto gige ti o tọ ati ti o tọ lori gbogbo ọlọ ijekuje.

Taabu.1 Alapin / Concave / Blade Isalẹ ijekuje ọlọ paramita

| Borehole Dia.Mill Shoe OD Niyanju Ipari (mm) (mm) Okun dabaru (mm) | PN Alapin | PN Concave | PN Bladed |

| 95.2- 101.6 89 2-3 / 8REG 250 | JM089FX | JM089CX | JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | JM097FX | JM097CX | JM097BX |

| 117.5- 127 110 2-7 / 8REG 250 | JM110FX | JM110CX | JM110BX |

| 130- 139.7 121 2-7 / 8REG 250 | JM121FX | JM121CX | JM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | JM130FX | JM130CX | JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | JM140FX | JM140CX | JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | JM156FX | JM156CX | JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | JM178FX | JM178CX | JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | JM200FX | JM200CX | JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | JM232FX | JM232CX | JM232BX |

| 273-295.3 257 6-5 / 8REG 250 | JM257FX | JM257CX | JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | JM279FX | JM279CX | JM279BX |

| 320.6-346.1 295 6-5 / 8REG 250 | JM295FX | JM295CX | JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | JM330FX | JM330CX | JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | JM381FX | JM381CX | JM381BX |

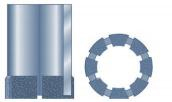

Rotari Bata

Bata Rotari gba awọn ohun elo carbide inu silinda lati ge oke ẹja alaibamu ni ayika, ati ni diẹdiẹ ṣe atunṣe oke ẹja ti o bajẹ sinu Circle kan, gẹgẹbi iwẹ, ara casing, ati bẹbẹ lọ.

[Akiyesi: Nitori iwọn ila opin ehin ti inu ti bata rotart tobi, iyipo yiyi tobi, nitorinaa titẹ kekere ati ipo yiyi lọra yẹ ki o gba ni lilo bata rotari.Ni gbogbogbo, titẹ liluho ko yẹ ki o kọja 10 KN ati iyara iyipo ko yẹ ki o kọja 50 r/min.]

Iru A

Ge irin, simenti ati Ibiyi.

Gige lori OD ati isalẹ.

Iru B

Ige irin ibi ti kiliaransi ni kekere.

Gige lori ID ati isalẹ.

Iru C

Ge Ibiyi.

Gige lori OD ati isalẹ.

Iru D

Ge dida ati ẹja ni akoko kanna.

Gige lori ID, OD ati isalẹ.

Tab.2 Rotari bata paramita

| Casing / Wellbore Dia. | Rotari bata OD (mm) | Rotari bata Gigun (mm) | Niyanju dabaru O tẹle | PN Rotari Bata | |

| 4ninu | 101.6mm | 95 400 | FJWP | TXX095 | |

| 5-1/2in | 139.7mm | 114 500 | FJWP | TXX114 | |

| 5-3 / 8 ni | 146.05mm | 118 500 | FJWP | TXX118 | |

| 6-5/8in | 168.28mm | 136 425 | FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | FJWP | TXX152 | |

| 7-5 / 8 ni | 193.68mm | 160 450 | FJWP | TXX160 | |

| 8-5 / 8ninu | 219.1mm | 185 550 | FJWP | TXX185 | |

| 12- 1/4 ninu 311. 15mm | 203 450 | FJWP | TXX203 | ||

| 15-5 / 8ni 396.88mm | 298 450 | FJWP | TXX298 | ||

| 20 ninu | 508mm | 406 450 | FJWP | TXX406 | |

Taper Mill

Taper ọlọ reams jade awọn ihamọ,collapsed casing ati liner ruju ati deburr whipstock windows and casing.The kekere opin ti taper ọlọ,pẹlu awọn oniwe-kekere,rọsẹ ti nwọ awọn pale casing ati liner.Then die-die spirled reamer egbegbe lati ọlọ kuro labẹ apakan si kikun. ọlọ opin.

Taper ọlọ oriširiši a conical ara ati tungsten carbide.Taper ti ara jẹ iwọn 30, konu naa jẹ apẹrẹ-ayẹ, ati pe dada jẹ lile tabi fifisilẹ tungsten carbide.

Tab.3 Taper ọlọ paramita

| Iho ikunra Dia. Taper ọlọ OD Ti ṣe iṣeduro Gigun (mm) (mm)Dabaru O tẹle(mm) | P.N. Taper ọlọ | ||

| 95-101.6 | 89 | 2-3 / 8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | XZ110 | ||

| 130- 139,7 121 2-7 / 8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5 / 8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346.1 295 6-5 / 8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

Elegede Okun Mill

Bata okun elegede jẹ ọkan ninu awọn irinṣẹ milling ni iṣẹ ṣiṣe sidetracking.O ti wa ni lo fun titunṣe casing, reaming ati šiši awọn ikanni.Nigbagbogbo a lo lẹsẹkẹsẹ lẹhin ṣiṣi awọn window.Eti milling (agbegbe iṣẹ) ti ọlọ elegede kan si ogiri borehole, ati opin eti kọọkan jẹ apẹrẹ bi konu.Nigbati a ba ṣii window naa, ọlọ elegede le ṣe gigun window lati oke ati yọ irẹjẹ ati awọn burrs ti o wa lori ogiri paipu lakoko gige akọkọ.

Tab.4 Elegede okun ọlọ paramita

| Borehole Dia.Dabaru (mm/ni) O tẹle | Agbegbe Ṣiṣẹ OD (mm/ni) | Gigun Agbegbe Ṣiṣẹ (mm/ni) | Gigun Totul (mm/ni) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168.3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177.8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Pilot ọlọ

A ṣe apẹrẹ ọlọ awaoko fun milling casing, liner, bata rotari tabi ọpọn ID nla.Awọn gige gige ti a wọ pẹlu awọn ohun elo tungsten carbide giga ti o jẹ ki ọlọ pilot Petrozhr le ṣaṣeyọri iyara iyara pẹlu wiwọ ti o kere ju.Awọn idoti gige kekere ati curled jẹ rọrun lati yọ kuro.Ati opin awaoko ti wa ni lo lati stabilize ninu awọn ID ohun ti o wa ni milled.

Tab.5 Pilot ọlọ paramita

| Iho ikunra Dia. (mm) | Dabaru O tẹle | Agbegbe Ṣiṣẹ OD (mm) | Gigun abẹfẹlẹ gige (mm) | Pilot agbegbe Ipari (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | LYMX331 | ||

Tungsten carbide aworan atọka

| Ohun elo ti a ṣe iṣeduro | Superloy | Opti-ge | Irin-muncher | Irin-muncher pẹlu Superloy |

| Washover ìmọ iho | √ | √ | ||

| Washover lu paipu | √ | |||

| Washover okuta wẹwẹ pack | √ | √ | ||

| Washover ikan gige | √ | |||

| Apoti fifọ | √ | |||

| Poilt ọlọ | √ | |||

| Loose Junk milling | √ | √ | ||

| Adaduro Packer tabi paipu tabi tubingjunk milling | √ | |||

| Milling elegede | √ | |||

| Milling okun | √ |

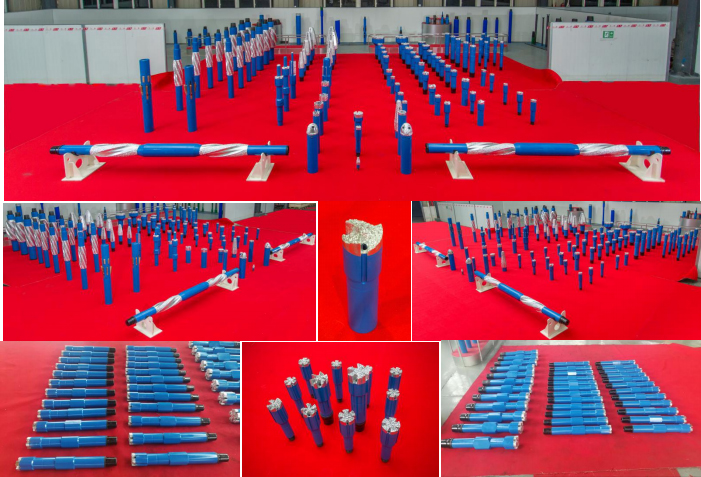

Awọn aworan Ipeja Ohun kan

Yara 703 Building B, Greenland aarin, Hi-tech idagbasoke agbegbe Xi'an, China

Yara 703 Building B, Greenland aarin, Hi-tech idagbasoke agbegbe Xi'an, China 86-13609153141

86-13609153141